Steam Superheaters series “SH-1000”

Steam superheaters “SH- 1 000” are equipment of a new generation, which does not have any existing direct analogues in the Russian and world markets. The superheaters are designed for superheating water steam and other gases in the wide range of temperatures from 200 to 1 200 C. The units of “SH- 1 000” series are constructed to be used in different industrial branches, and also for the developments of new technological procedures in research labs.

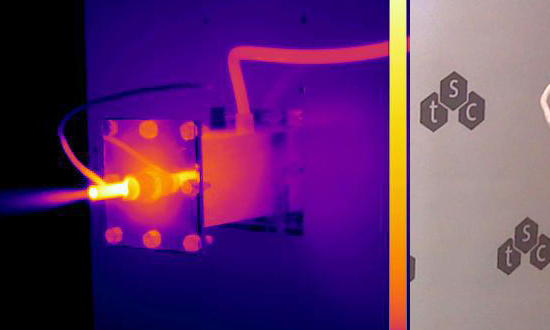

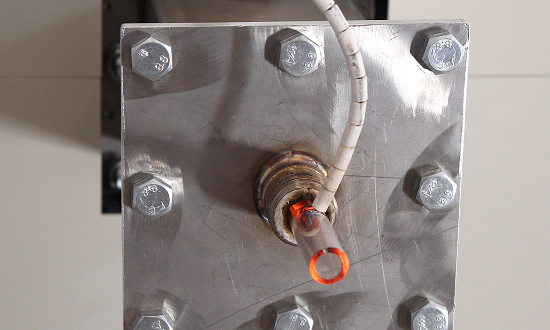

In the steam superheaters, there is a new technology of heat transfer and an innovative construction that enable to obtain unique characteristics of heat transfer. Apart from gas superheating the units “SH- 1 000” can be applied as high temperature chemical reactors.

TECHNICAL FEATURES

- Obtaining superheated steam at atmospheric pressure

- Only electrical power is required

- Modest weight-size parameters

- Mobility of equipment

- Long operational life

- Productive capacity for lab units from 6 kg/h

- Productive capacity for industrial units from 20 kg/h

DESCRIPTION OF STEAM SUPERHEATERS

Steam superheaters series “SH- 1 000” is especially designed for the following areas:

1. Chemical reactors

2. Pyrolysis and carbonization of various organic substances

3. Waste recycling along with obtaining synthesis gas and liquid fuel

4. Gasification of organic materials

5. Recycling low-graded coal and waste from coal-mining and timber manufacturing industries along with obtaining synthesis gas and liquid fuels

6. Conversion of methane and associated gas along with obtaining synthesis gas and industrial hydrogen

7. Advanced recycling of carbon hydride in petrochemical and chemical industries

8. Obtaining carbon nanomaterials

9. Obtaining high-quality activated carbons

10. Regulating and sustaining required stoichiometry of chemical reactions

11. Scientific research and development of new technological procedures in high level non-waste recycling of waste and raw materials

12. Purification of gas emissions

13. Purification of technological surfaces from carbon depositions

14. Food-manufacturing and pharmaceutical industries

For the last years a vast number of scientific research and experimental developments have been conducted in multiple branches of chemical and processing industries. They were aimed at advanced recycling of raw materials and efficiency improvement. These research works show that integration of the heated steam with the range of temperatures from 600 to 1 000 C into present technologies enables to essentially increase the product outturn, to remove unwanted components, to decrease contaminants emissions, to regulate conducted chemical reactions and the ratio of its released components. Building new structures of waste recycling along with using high temperature steam allows obtaining close-curcuit and non-waste systems. However, the implementation of these high-level solutions in industrial environment has been hindered so far by the fact of non-existent equipment and “know-how’’ technologies of obtaining high temperature superheated steam. The present day commercial superheaters, operated by means of burnt hydrocarbon fuel, allow obtaining steam with the temperatures of no more than 700 degrees Celsius. They have big size, not sufficient service life, high cost, and complicated infrastructure, which make it impossible to use them in experimental works and many industrial procedures.

Superheaters of “SH-1 000” series use a new method of steam superheating and enable to heat steam to the temperatures unavailable for the rest of produced equipment. Modest size, building block concept and scalability of our units allow us to offer our customers both standardized and individual solutions to integrate the superheaters into their present technological chains.

ADVANTAGES

1. Superheated steam of atmospheric pressure.

Units “SH- 1000” enable to obtain superheated steam under atmospheric pressure. Work with high pressures is not required to superheat steam. This allows a significant simplification of production infrastructure.

2. A wide range of working temperatures.

Units “SH- 1 000” enable to superheat gases in a wide range of temperatures. Temperature of heat is regulated automatically. This allows using steam superheaters in different technological procedures.

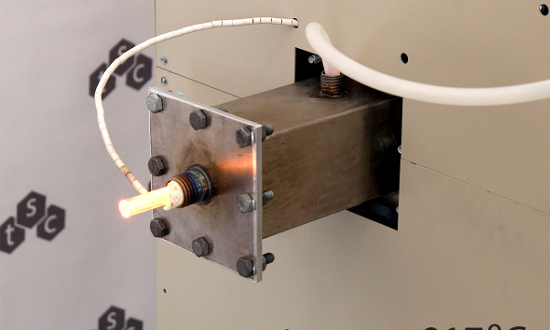

3. Modest size

Steam superheaters “SH- 1 000” have modest size and weight, which allows to move them easily when necessary. This is especially convenient in laboratory environment.

4. Only electrical power is required for operation.

To operate units “SH- 1 000” only electrical power is required. Now there is no need to burn hydrocarbons and expensive gases to obtain high temperature heat. This significantly simplifies production infrastructure and has more favorable costs.